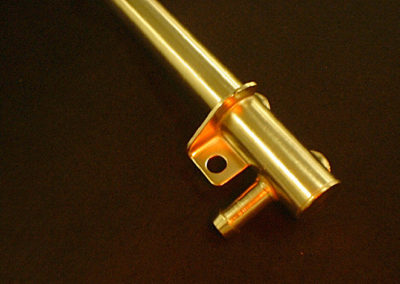

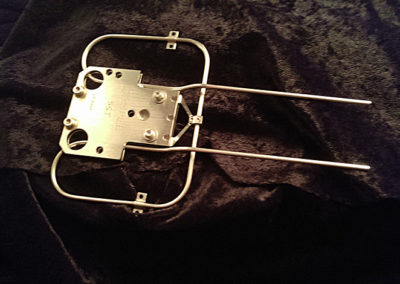

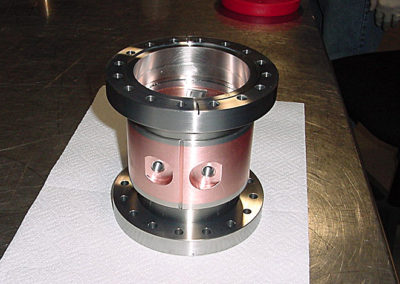

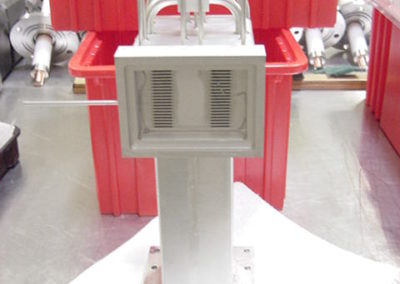

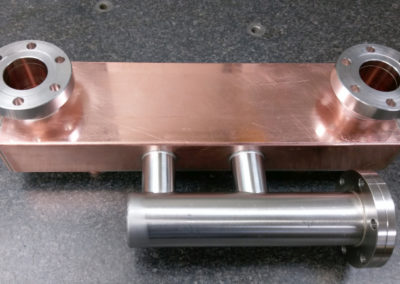

Metal to metal vacuum brazing opens up many design possibilities. Often, design features are not conducive to welding. Vacuum brazing allows the bonding of problematic design features. Also, some combinations of metals, are not weldable. Vacuum brazing opens the possibility of joining different metal combinations with very robust results and in a very clean manner.

The vacuum brazing can be done on a one-off basis or batch fired making it a very efficient process.

The benefits of vacuum brazing include:

• Full joint penetration – no virtual leaks.

• No induced contamination or trapped oxides.

• Allows the joining of multiple metals.

• Allows the joining of metals that are difficult or impossible to weld or braze in other atmospheres.

• Price competitive with welding.

• The vacuum brazing process cleans metal surfaces of any organic contaminants.

• Most metals can be vacuum brazed.

• Full joint penetration – no virtual leaks.

• No induced contamination or trapped oxides.

• Allows the joining of multiple metals.

• Allows the joining of metals that are difficult or impossible to weld or braze in other atmospheres.

• Price competitive with welding.

• The vacuum brazing process cleans metal surfaces of any organic contaminants.

• Most metals can be vacuum brazed.